-

Product advantage

1. Non-combustible grade: A1;

2. The material is smooth, sticky and easy to construct;

3. Strong water retention rate, good impermeability;

4. Greater bonding strength and good volume stability.

-

Product parameter

Product specification: 20kg/bag

Executive standard: Q/HXXC M01-2020 Mortar for Gap Filling of Door and Window Frames

-

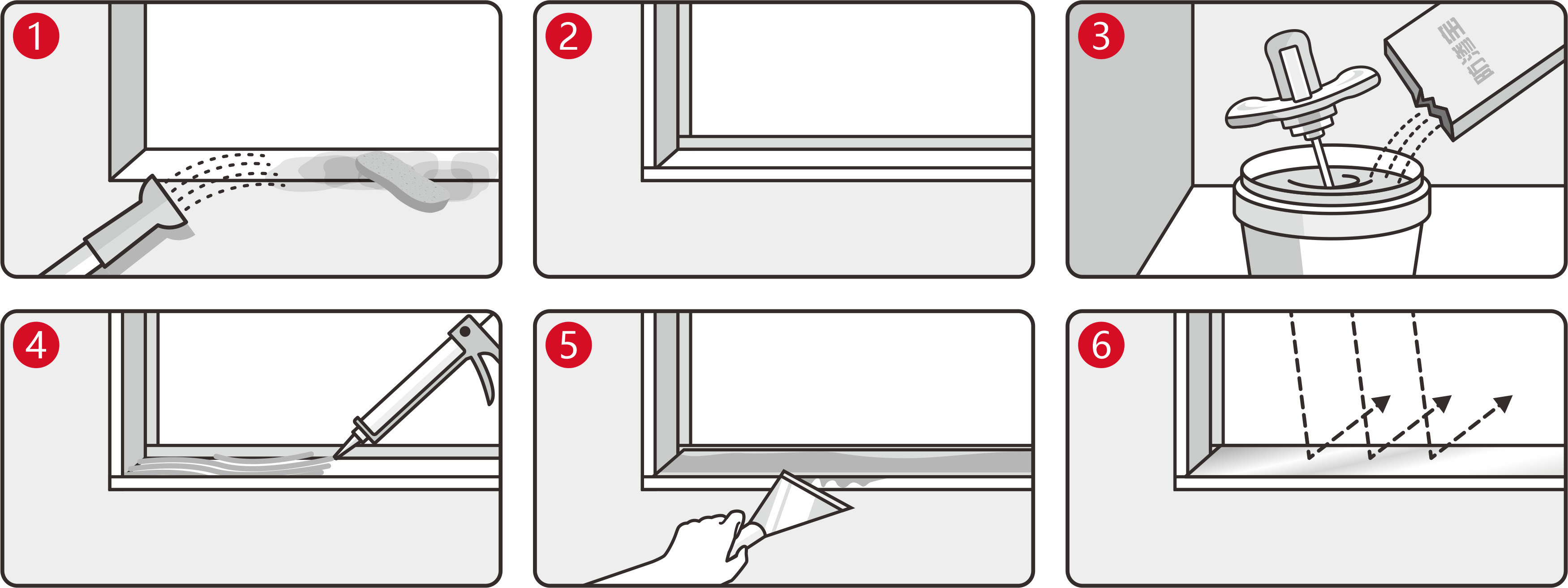

Construction process

Step One:“Cleaning and wetting”

Confirm that the window frame is fixed;

Confirm that concrete chips, wood chips, etc. have been cleaned up;

Confirm that there is no oil, mud and other pollutants;

Confirm that the gaps in the wall have been repaired;

Rinse the construction base surface with water or spray water with a watering can to wet the construction base surface.

Step Two: "Leak stoppage treatment"

In order to prevent the anti-seepage material from being exposed outside the wall, baffles or PE rods shall be set up in advance for filling. The diameter of the PE rod shall be selected based on the width of the gap, and the diameter is generally 2-2.5cm.

Step Three: “Anti-seepage material mixing”

The ratio of product powder to water is about 1:0.38, that is, 10kg powder + (3.6~4.0kg) clear water;

Pour the anti-seepage powder into the mixing bucket, and add clear water while mixing;

Put all materials into the mixer and then mix for 90s. If the mixing state is not good at this time, turn off the mixer, turn the materials over with a small shovel and then mix for 60s.

Step Four: “Gap filling with anti-seepage materials”

Put the mixed anti-seepage materials into the filler, and insert the pressure gun as deep as possible. Make sure that the corners can also be filled with anti-seepage materials, and the filling sequence is from bottom to top to ensure that there is no gap after filling.

Step Five: “Completion”

Smooth the anti-seepage materials within 1h after filling to make the surface of the window frame level. Remove the baffle or PE rod and use a trowel for pressing to ensure that there is no gap. Use a brush to make the connection part between the concrete and the filled anti-seepage materials more coordinated.

Step Six: “Cleaning and maintenance”

Use a brush to remove the stains of anti-seepage materials that pollute the surface of the window frame, and clean up the filled anti-seepage materials that have fallen on the floor. When there is a possibility of getting wet by rain, freezing in winter, or being exposed to direct sunlight in summer, a thin film shall be covered for maintenance.