-

Product advantage

1. Applicable size: facing tiles ≤600*600mm.

2. Formaldehyde-free, odorless, and grade 0 anti-mildew.

3. Cement and aggregate are specially selected by Huaxin Cement, a century-old brand, for the Huaxinshifutile adhesive, and the quality control is stable. The gelatine powder is the best gelatine powder selected from the international manufacturer BATF, with excellent quality.

4. It is easy to use the product for construction, and the product can be used immediately after opening the package and adding water. Excellent formula makes construction smoother, and the construction difficulty is grade 0.

5. Compared with competitive products of the same standard, the product has stronger adhesion and can be used for fixing larger tiles, and more materials can be saved when the thin tile fixing method is used.

-

Product parameter

Product specification: 20kg/bag

Ratio: mix water and powder in a ratio of about 1:5, i.e. (3.8-4.6) clear water + 20kg tile adhesive

Executive standard: GB/T 25181-2019 DTA Ⅰ

Scope of application: It is widely applicable to decorative parts of indoor walls and floors with the base surface of concrete, ordinary mortar, self-leveling mortar, masonry, etc. It is mainly used for fixing ordinary ceramic tiles with a water absorption rate ≥ 3% and a single tile size ≤ 600mm*600mm.

-

Serviceable range

The product is made from preferred natural mineral raw materials, and is a polymer modified cement-based tile adhesive. It is mainly used to fix decorative materials such as ceramic tiles, facing tiles, floor tiles, etc., completely solving the problem of weak and unstable bonding with traditional mortar. It is easy to use the product for tile fixing; the product has super strong adhesion and excellent flexibility, and is green, environment-friendly, healthy and safe.

-

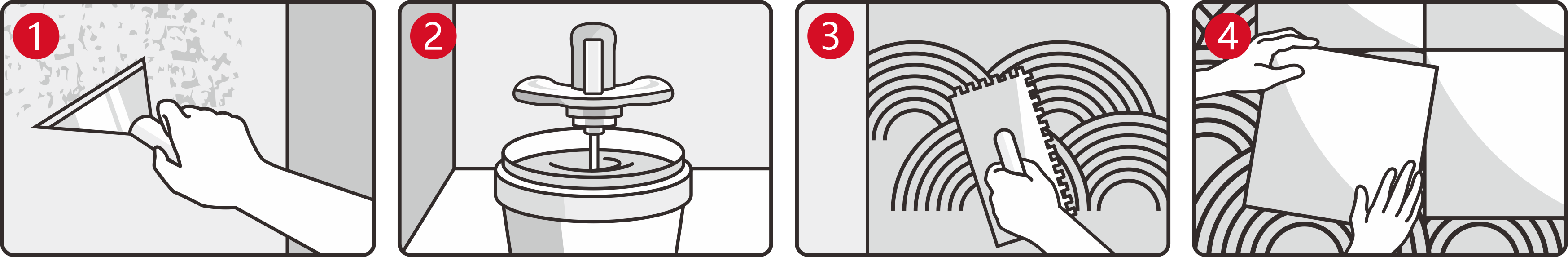

Construction process

Step 1: “Base surface treatment”

The base surface shall be dry, firm, flat and free of oil stains, dust, and release agents.

Step 2:“Adhesive mixing”

Pour the required clear water into the “mixing bucket”, then pour in the powder, and mix water and powder in a ratio of about 1:5, that is, (3.8-4.6) clear water + 20kg tile adhesive. Use an electric mixer to mix them until they are uniform and lump-free. The mixed adhesive shall be used up within 2h (when the temperature is relatively high and there is abundant sunlight, it shall be used up in a shorter time).

Step 3:“Applying the mixed adhesive”

Use a professional “toothed scraper” to evenly apply the mixed adhesive on the working surface in batches, and apply it on about 1m2working face in each batch.

Step 4:“Tile fixing & pressing”

Apply the mixed adhesive on the back of the tiles to be fixed. When fixing the tiles, press the tiles on the base surface by hand, or adjust the parallelism of the tiles by lightly tapping with a rubber hammer until the tile surface is flat. The tiles fixed within 15 minutes can be moved to correct their position.

-

Notes

✔ Generally, tile boards do not need to be soaked in water. For tiles or base courses with strong water absorption capability, they shall be soaked in water for several minutes or wetted by spraying water.

✔ The verticality and flatness of the substrate must be confirmed before construction.

✔ The construction temperature is 5-35°C, and the mixed adhesive shall be used up within 2h. Do not mix the dried mixed adhesive with water.

✔ Attention shall be paid to reserving expansion joints during tile fixing. The initial strength after tile fixing is low, so heavy load on the tile surface shall be avoided within 24h. Stepping or joint filling is allowed only after 24h.