-

Product advantage

1. Its color can prevent missing application.

2. With ultra-low VOC emission value, it is more environment-friendly and healthy.

3. It has resistance to flexibility, stretching and deformation.

4. It has good anti-penetrability performance and good anti-efforescence performance.

5. It can be applied on wet base surfaces with low requirements for construction environment.

6. Huaxin'sown factory supplies high-quality special cement, multi-graded fine aggregate, etc., and other raw materials are purchased from world-class well-known enterprises such as BASF, Sika, Dow, Wacker, Avebe, JSR, etc., ensuring the supply of high-quality raw materials and stable quality, so it is a healthy and environment-friendly ecological auxiliary material.

7. Compared with other similar brand products, it has a higher liquid-to-powder ratio (1:2.5), and the application area is 20% larger than that of other brand products, which greatly saves materials and costs.

-

Product parameter

The product is a two-component cement-based waterproof paint composed of organic liquid material (composed of high-quality polymer emulsion and various functional additives) and inorganic powder material (made from Huaxin special cement, multi-graded fine aggregate and additives) in a scientific proportion.

-

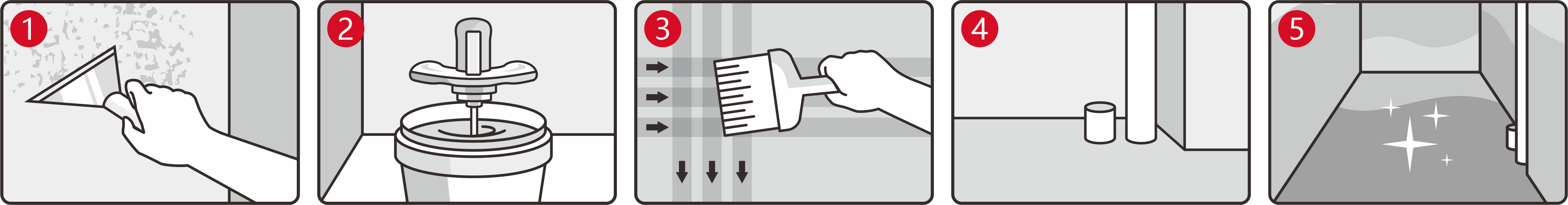

Construction process

Step One: Base surface treatment

It must be ensured that the base course is flat, firm, clean and free of oil stains and dust. Before the use of the product, the base surface shall be fully wetted with clear water, but there shall be no accumulated (visible) water.

Step Two: Additional treatment at details

Before application, the node parts shall be reinforced. The internal and external corners shall be made into arc angles; for parts with cracks and reserved grooves at the pipe root, leaking stoppage materials shall be used to reinforce the waterproof layer; the holes or low recesses shall be filled with mortar for leveling; when the base course is loose or the base surface has a high water absorption rate, an interface treatment agent can be used for sealing treatment first.

Step Three: Mixing

Use one bag of liquid material with one bag of powder material. Pour the liquid material into a clean mixing bucket first, use an electric mixer and slowly pour in the powder material in the mixing process, and mix for a few minutes until the slurry in the bucket is uniform without stratification and without lumps.

Step Four: Multiple coatings applied at large areas

The waterproof coating shall be applied multiple times, fully and evenly, and at least 2-3 coatings shall be applied. The next coating can be applied only after each coating is dry, and the application direction shall be perpendicular to that of the previous coating, and the cross application method shall be used. The thickness of each coating applied shall not exceed 1mm, and one more coating shall be applied at weak waterproof parts to ensure the waterproof effect.

Step Five: Inspection and acceptance of waterproof layer

Use the product in areas such as kitchens and bathrooms, and conduct the water tight test after the coatings are completely dry. The acceptance time shall not be shorter than 24h.

Step Six: Protective layer construction

After passing the acceptance, the protective layer construction shall be carried out according to the relevant standard design specifications.

-

Notes

✔ Before construction, the paint shall be mixed fully and evenly, and the prepared slurry shall be used up within 1h, and water shall not be added at will.

✔ The temperature during construction shall be between 5°C and 35°C, and it is forbidden to carry out construction in windy, rainy and snowy weather.

✔ Before hard drying of the coatings, no other operations shall be carried out on the coatings, so as not to damage the protective layer and affect the waterproof effect.

✔ The thickness of the waterproof coating should be 1.2mm.