-

Product advantage

Good adhesion, Strong permeability and good sealing performance, Convenient construction, Healthy and environment-friendly.

-

Serviceable range

1. It is suitable for reinforcing the loose sand layer on the floor;

2. It is suitable for surface reinforcement treatment before cement plastering and mortar repairing;

3. It can be used in the construction of waterproof layer to improve the bonding capability of the interface before tile fixing.

-

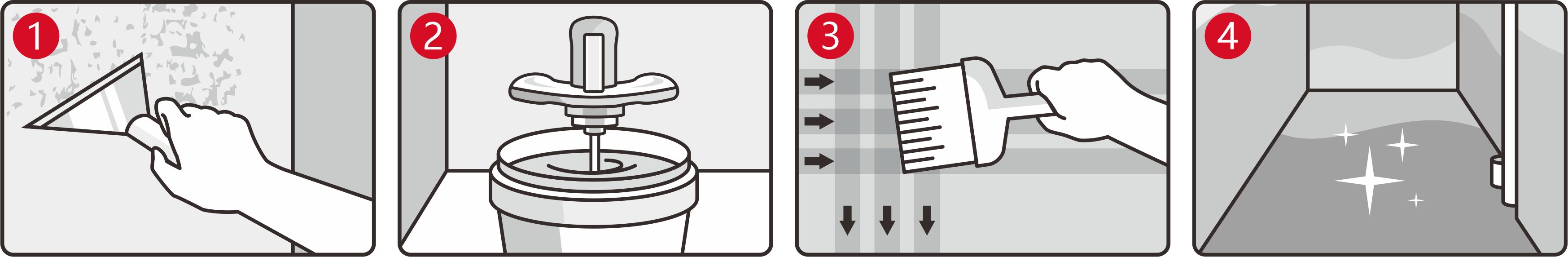

Construction process

Step One: Base surface treatment

First remove the dust, oil stain and loose layer on the surface of the base course and ensure that the wall is clean and free of dust, grease and other substances that affect the bonding performance.

If there are, pothole and cracking phenomena on the surface of the base course , ordinary cement mortar shall be used for repair first.

Step Two: Mixing

It is recommended to use a hand-held electric device for mixing, so that the product can be mixed evenly before use.

Step Three: Application and drying

The product shall be applied to the base surface by roller, and shall be applied as a whole.

Step Four: Maintenance and finished product protection

Ventilation must be strengthened, and natural maintenance is enough. The subsequent process can be started only after the product is hard-dried and the base surface is completely sealed.

-

Notes

✔ The product is prohibited from being mixed with other adhesive products

✔ A small amount of stratification is normal and doesn't affect product quality and construction effect

✔ During construction, the on-site air circulation shall be ensured and direct sunlight shall be avoided

✔ If the product accidentally comes into contact with eyes, rinse immediately with plenty of clear water and seek medical attention timely