-

Product parameter

Product specification: 20kg/bag

Executive standard: JG/T298-2010 Type Y standard Putty for Interior

-

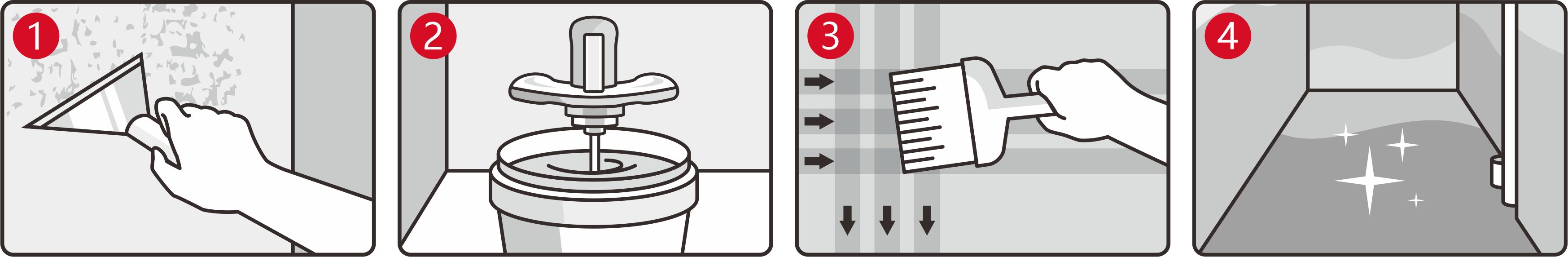

Construction process

Step One:“Base course treatment”

The base course shall be solid, clean and roughly flat; the PH value shall be less than 10, and the water content shall be less than 5%; if the base course has a high water absorption rate, it shall be wetted with clear water or treated with an interface agent in advance.

Step Two:“Adding water and mixing”

Pour water into the bucket (the mass ratio of putty to clear water is about 100:33~36), and add the powder material while mixing. The mixing time shall be 5-8 minutes, mixing shall be stopped for 2 minutes, and then the second mixing shall be carried out for 2 minutes before use.

Step Three: “Applying the mixed adhesive”

The second layer shall be applied until the first layer is completely dry, and the time interval shall be ≥ 4h in summer and ≥ 24h in winter. (Actually, it varies due to the local climate and the coating thickness of putty during construction).

Step Four:“Wall grinding”

After 2-3 layers are applied, grinding can be carried out.

-

Notes

✔ The temperature on the construction site shall be between 5°C and 35°C.

✔ Avoid applying it at the same time of applying the polyester paint.

✔ After 2-3 layers are applied, grinding can be carried out.

✔ Don't use too coarse sand paper during grinding. It is recommended that the fineness of sand paper should be between 200 and 300 meshes.