-

Product parameter

Product specification: 50kg/bag

Executive standard: Special Mortar for Autoclaved Aerated Concrete Wall

-

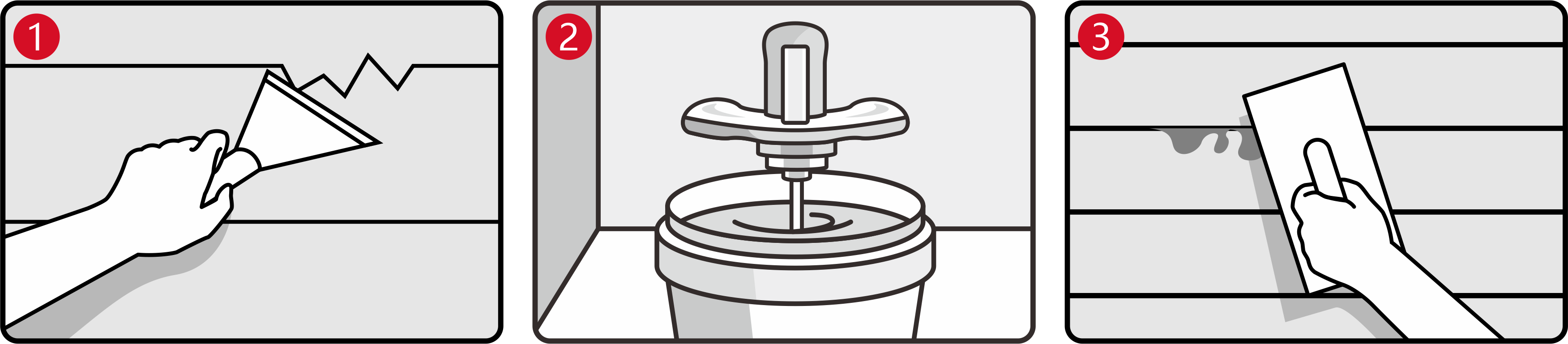

Construction process

Step One:“Base course treatment”

Clean up the blocks to ensure that the base surface is solid and free of cracks, dust, oil stains, stains, release agents and other media; blocks with defects such as falling corners shall be repaired.

Step Two:“Material mixing”

Pour an appropriate amount of clear water into the mixing bucket first, and then add the powder into the mixing bucket in a ratio of powder to water ≈ 4:1. Use a hand-held mixer for mixing until the material is uniform without lumps. Let it stand for 5 minutes, and then mix it again before use.

Step Three:“Construction”

Spread the mixed mortar evenly on the blocks, and pay attention to correcting the levelness and perpendicularity of the blocks.

-

Notes

✔ The temperature on the construction site shall be between 5°C and 35°C.

✔ The product shall be added with water in strict proportion before use, and it is strictly prohibited to mix the product with cement, sand and other materials;

✔ The mortar shall be used up within 2h, and it is forbidden to use the dried mortar after being adding with water;

✔ The dry construction method shall be used, and there is no need to water the blocks. When the temperature is high and the base surface is too dry, it shall be wetted with clear water first;

✔ Outdoor construction should not be carried out in rainy days.