-

Product parameter

Product specification: 50kg/bag

Executive standard: Q/HXXC ZHSJ-2019 Bonding Mortar

Scope of application: It is applicable to decorative parts of indoor walls and floors with the base surface of concrete, ordinary mortar, self-leveling mortar, masonry, etc. It is mainly used for fixing ordinary ceramic tiles with a water absorption rate of>0.5% and a single tile area ≤ 600mm*600mm on the floor, fixing ordinary ceramic tiles with a water absorption rate >6% and a single tile area ≤ 300mm*300mm on the wall and bonding ordinary masonry and blocks (excluding aerated and lightweight bricks).

-

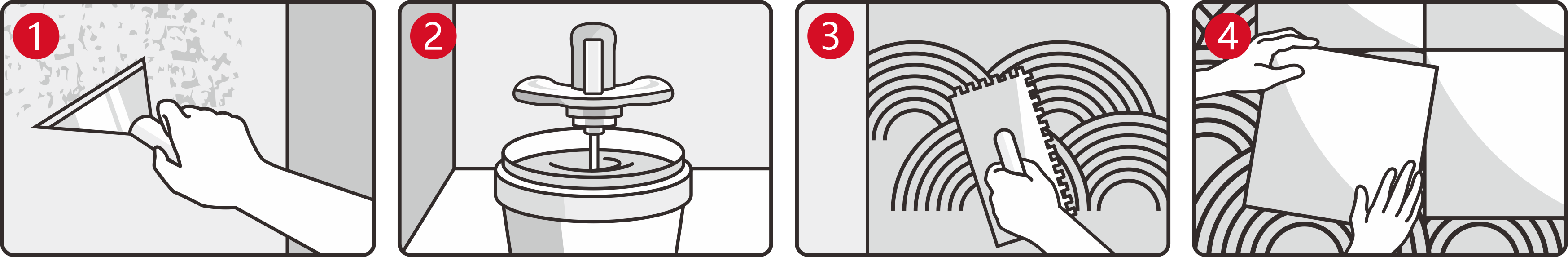

Construction process

Step One:“Base surface treatment”

The base course must be solid, stable and free of loose sand. The surface of the base course shall be free of laitance, cracks, dust, oil stains, release agents and other substances that hinder bonding, and shall be treated. For the base surface that has a high water absorption rate or is very dry, it shall be wetted before construction, and the construction can only be carried out after the surface is dry and free of visible water.

Step Two:“Mixing of bonding mortar”

Pour the weighed clean water into the mixing bucket first, then mix the product in a ratio of powder to water ≈ 4:1 until it is uniform without lumps. Let it stand for 5 minutes, and then mix it again before use. The bonding mortar shall be used up within 2h.

Step Three:“Applying the mixed adhesive”

Use a professional “toothed scraper” to evenly apply the product on the base surface in batches, and apply it on about 1㎡working face in each batch.

Step Four:“Tile fixing & pressing”

Apply the bonding mortar to the back of the ceramic tile to be fixed. When fixing ceramic tiles, press the ceramic tiles on the base surface by hand, or adjust the parallelism of the ceramic tiles by lightly tapping with a rubber hammer until the tile surface is flat. The ceramic tiles fixed within 10 minutes can be moved to correct their position.

-

Notes

✔ The environment temperature during construction should not be lower than 5 ℃ and higher than 35 ℃;

✔ For the thickness of ceramic tile fixing, consideration shall be given to the size of the selected toothed scraper, the backside pattern of the ceramic tile, and the flatness of the base.

✔ In the mixing process, it is strictly prohibited to add additional materials such as cement and sand. The bonding mortar shall be used up within 2h, and it is forbidden to use the dried bonding mortar after being adding with water;

✔ Attention shall be paid to reserving expansion joints during tile fixing. The initial strength after tile fixing is low, so heavy load on the ceramic tile surface shall be avoided within 24h. Stepping or joint filling is allowed only after 24h.