-

Product parameter

Product specification: 20kg/bag

Ratio: mix water and powder in a ratio of about 1:0.22

Executive standard: JC/T 985-2017 Cementitious Self-leveling Floor Mortar

-

Serviceable range

The product can be used for light-load indoor floor leveling in homes, offices, villas, etc., and decoration layers such as floors, tiles and carpets can continue to be fixed in the future.

-

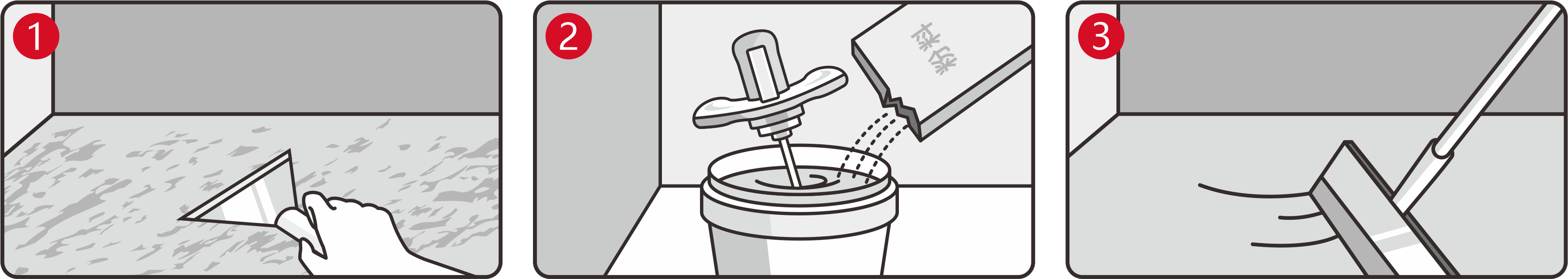

Construction process

Step One: “Base surface treatment”

Newly poured concrete needs to be cured for longer than 28d;

The concrete strength on the base surface shall be above C20, and the water content shall be less than 10%. The laitance, oil stains, pollutants, etc. on the surface shall be removed and the defective parts shall be repaired;

After the base course is treated, use a special interface agent to seal the base course.

Step Two:“Self-leveling and mixing”

Pour clean water into the mixing bucket (the weight ratio of powder to water is 1:0.22, and the packaging is 20kg/bag, that is, 4.4kg of water is added to each bag);

Add powder while mixing, and mix for 3-5 minutes until the material is uniform without lumps. Let it stand for 2-3 minutes before spreading it. Note: The mixed material needs to be used up within 20 minutes (in areas with high temperatures and abundant sunlight, it needs to be used up in a shorter period of time).

Step Three:“Applying the mixed adhesive”

According to the thickness requirements during construction, adjust the teeth length of the special scraper for self-leveling for spreading;

Timely use the defoaming roller for cross defoaming.

-

Notes

✔ Please confirm that personal protective equipment (PPE) is worn before using the product.

✔ Before construction, it must be confirmed that the base surface treatment meets the construction requirements.

✔ The mixed self-leveling product shall be used up within the specified time. Do not mix the dried slurry with water again

✔ Pay attention to the treatment at the overlapping joints during construction. Do not proceed to the next step of construction before the product is completely dry.

✔ The construction thickness is 1-6mm.